VEM GmbH

Booth number: 2D-04

www.vem-group.com

About us

VEM is one of the leading manufacturers of electrical drive technology for shipbuilding and can look back on 140 years of tradition in electrical engineering.

VEM develops and manufactures generators and motors for vessels up to a total weight of 200 t, which are in operation worldwide. These include cruise ships, yachts, ferries, container ships, tankers or special vessels, which are equipped with shaft or diesel generators, POD drives, thruster or propulsion motors as well as auxiliary drives. VEM supports its customers from the development of the idea, through design and production, right up to delivery of the product and during operation.

Wide power spectrum - unlimited application possibilities for standard motors

The low-voltage machines for auxiliary drives are characterised by extraordinary operational reliability, a long service life and efficiency due to high efficiencies as well as their ability to be modified. These attributes ensure universal application scenarios for VEM low-voltage machines. From winch drives on cargo ships to motors for the air-conditioning of modern cruise liners, the standardised motor series offer a wide range of choices.

VEM as a pioneer in hybridisation and electrification

Our water-cooled permanent magnet motor series with the power range of 37 kW to 16 MW enables high efficient operation. A very compact as well as lightweight design and very high system efficiencies are crucial for integration in modern systems - as generators or propulsion motors.

Turning the tide for cargo and container ships - shaft generators from VEM

Shaft generators are the guarantee for efficient system design and compliance with the latest emission standards for merchant vessels. VEM builds and supplies these in various designs, e.g. as electrically excited machines, as they have been in use for many decades. But also as permanent-magnet excited variants, in order to be able to save installation space and mass.

Powerful, quiet and efficient - VEM propulsion motors

Cruise ships, mega yachts and research vessels rely on the noise-optimised drives. In particular, the specially developed decoupling mechanisms and the system understanding of the development engineers are the foundation of success.

Address

Pirnaer Landstraße 176

01257 Dresden

Germany

E-mail: vemgmbh@vem-group.com

Phone: +49 351 2080

Internet: www.vem-group.com

Contact person:

Marco Macion

Sales Director Marine Solutions

E-mail: marco.macion@vem-group.com

Phone: +49 351 208 2203

Peter Focke

E-mail: peter.focke@vem-group.com

Phone: +49 172 372 9133

Zheng Lu

Deputy General Manager

E-mail: zheng.lu@vem-group.cn

Phone: +86 159 008 945 16

Dihui Shan

Sales Manager

E-mail: dihui.shan@vem-group.cn

Phone: +86 158 210 049 22

Chuhu Mao

Marketing Specialist

E-mail: chuhu.mao@vem-group.cn

Phone: +86 182 515 448 33

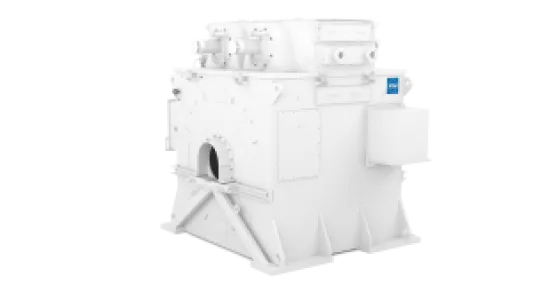

Main propulsion motors for marine applications

VEM offers motor solutions that are tailored to different areas of application and requirements. The solutions include horizontal direct drive motors, which are characterized by their efficiency and reliability and are ideal for use in various industrial applications. In addition, VEM offers vertical azimuth motors specifically designed for applications where precise control of the direction of rotation is required. These motors are ideal for use in ships and other vehicles that require precise control of the direction of movement.

Another highlight of VEM's offering are the high-speed motors for transmission solutions, such as PTI (Power Take-In) and PTO (Power Take-Off). These motors are particularly powerful and allow for high speeds, making them perfect for applications where speed and performance are crucial. Overall, VEM offers tailor-made drive solutions for a variety of industrial and maritime applications.

Horizontal motors for direct drive

Large, slow-running engines are increasingly being used to power modern ships. These motors are designed for operation on medium or low voltage converters.

Possible drive variants

Operation on a converter with one or more winding systems

Start-up via soft starter up to the highest performance

Combination of direct and controlled drive (tandem)

Possible machine types

Permanently excited synchronous motors

Separately excited synchronous motors

Asynchronous motors

Specifications

Low voltage or medium voltage

up to 30,000 kW

Vertical motors for azimuth drives

The azimuth drive is the result of the compact design of POD drives and the robust technology of standard drives. L drives replace the Z drives previously used due to their higher efficiency and lower space requirements.

Advantages of the drive concept

Extremely compact system with integrated drive motor

Minimizing installation costs at the shipyard

Increased efficiency due to the elimination of the topwater gearbox

External testing possible on a test stand before installation

The drive on the system is freely accessible

Possible machine types

Permanently excited synchronous motors

Asynchronous motors

Specifications

Low voltage or medium voltage

up to 16,000 kW

Main drives for water jets or on the gearbox

Electrification is also finding its way into high-speed ferries. The biggest challenge is the mechanical integration into the hull and compliance with the weight specifications. Previously used by internal combustion engines. Today and in the future, electric motors will replace them. VEM offers highly efficient drive motors for customer-specific applications.

We configure PTI/PTO applications according to your performance and speed specifications exactly for your application. Our electric drives are offered with rolling or plain bearings. They increase the overall efficiency of the ship. In cross-connect mode, they also reduce operating times and maintenance costs for the main machines. These drives are therefore particularly suitable for retrofits.

Possible machine types

Permanently excited synchronous motors

Asynchronous motors

Specifications

Low voltage or medium voltage

up to 5,000 kW

Thruster motor for marine applications

Thruster and transverse thruster motors

Thrusters are used on many types of ships. These positioning devices have become an indispensable part of large ships. Especially for special and work vessels (wind farms, oil and gas platforms), the output of these drives can be up to 5 megawatts. The machines can be operated via a frequency converter or directly on the mains (DOL) in operating mode S1 or S2.

Possible machine types

Permanently excited synchronous motors

Asynchronous motors

Specifications

Low voltage or medium voltage

up to 5,000 kW

Generators for Marine Applications

In-Line Generators (Slow-Speed, PTO / PTI / PTH)

The new series of slow-running three-phase shaft generators is available as a permanently excited synchronous machine (PMSG) or as an electrically excited synchronous machine (EESG) in a salient pole design. These shaft generators are extremely reliable and efficient with lowest maintenance costs. They are mounted directly on the main shaft and do not have their own bearings.

Depending on the torque, five different sizes are used. This means that VEM probably offers the greatest variability on the market.

Possible machine types

Permanently excited synchronous generators

Electrically excited synchronous generators

Shaft heights (900, 1120, 1400, 1600, 2000)

Specifications

Low voltage and medium voltage

Up to 16,000 kVA (or 1,800 kNm mechanical)

Up to 150 min-1

Medium-speed generators

VEM medium-speed generators are designed with a welded housing, as full-pole or salient-pole machines and brushless excitation or permanently excited synchronous machines.

The machines are equipped with digital controllers and associated monitoring according to customer requirements. In addition to rolling bearings for smaller capacities, flange-mounted plain bearings are mainly used. For generators with high outputs, the bearings are also delivered as pillow block bearings with the complex oil supply systems required for this.

Possible machine types

Permanently excited synchronous generators

Electrically excited synchronous generators

Specifications

Low voltage and medium voltage

Up to 30,000 kVA

Up to 750 min-1

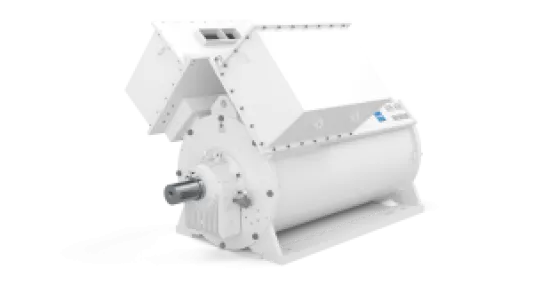

High Speed Generatos/Motors (PTO / PTI / PTH)

The new series of extremely compact, water-jacket-cooled, high-speed shaft generators is characterized by its low weight and highest levels of efficiency.

Possible machine types

Permanently excited synchronous generators

Electrically excited synchronous generators

Specifications

Low voltage

Up to 4800 kVA

Up to 1800 min-1

Auxiliary machines for ship applications

Thousands of VEM motors are reliably used on vessels worldwide. Depending on the field of operation, VEMs auxiliary machines drive compressors, anchor and mooring winches, hoists, fans in cooling and air conditioning systems as well as cutter heads or dredger pumps or feed pumps for oils, fuels, process and fire-fighting water.

Special marine motors, low or medium voltage

Our product range includes low-voltage machines for auxiliary drives. These motors are characterized by exceptional operational reliability, a long service life, effectiveness and environmental friendliness due to high efficiencies as well as its ability to be modified. These attributes ensure universal application scenarios for the VEM standard marine motors. Most of our standard marine motors have a type approval by the most common classification societies.

Specifications

Shaft heights 450 and beyond

50 / 60 Hz

up to 5000 kW

variable speed

Standard marine motors in low-voltage version

There are also pole-changing motors in a robust gray cast iron design for winch drives on cargo ships or motors for air conditioning on modern cruise ships. The joint success is based not least on the individual and high-performance mechanical engineering, on the basis of which we produce our portfolio for shipbuilding.

The efficiency classes of IEC standard motors, defined in the IEC 60034-30 standard, characterize the energy consumption of the motors. These classes range from IE1 (Standard Efficiency) to IE4 (Super Premium Efficiency). Motors with higher efficiency classes consume less energy and therefore contribute to lower operating costs and a better environmental balance. Choosing a motor with a higher efficiency class can therefore offer both economic and ecological advantages. VEM generally suggests using efficiency class IE3 or higher.

For operation in potentially explosive areas, VEM standard marine motors with different types of ignition protection can also be used as auxiliary drives.

Specifications

shaft heights 56 to 450

50 / 60 Hz

Up to 1,000 kW

IE3 or higher